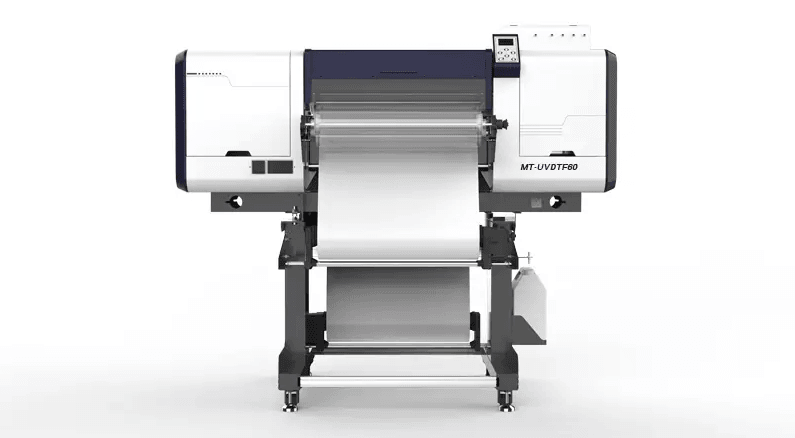

The MTuTech UV DTF Printer represents a revolutionary advancement in digital printing technology. Known for its precision, versatility, and efficiency, this printer is an essential tool for any print shop aiming to achieve high-quality results. Whether you are new to UV DTF printing or looking to optimize your existing setup, this guide provides comprehensive insights into using the MTuTech UV DTF Printer effectively.

1. Understanding UV DTF Printing Technology

UV DTF (Direct-to-Film) Printing combines the benefits of UV printing with film-based transfer technology. This process involves printing designs onto a special film using UV-curable inks, which are then transferred onto various substrates. The key advantages of UV DTF printing include vibrant color reproduction, durability, and versatility across different materials.

2. Setting Up Your MTuTech UV DTF Printer

Proper setup is crucial for achieving optimal print quality and performance. Follow these steps to set up your MTuTech UV DTF Printer:

- Unboxing and Assembly: Carefully unbox the printer and assemble any required parts according to the manufacturer’s instructions. Ensure all components are securely connected and aligned.

- Placement: Position the printer on a stable, level surface with adequate space for operation and maintenance. Ensure proper ventilation to avoid overheating.

- Connecting to Power and Network: Plug the printer into a suitable power source and connect it to your network or computer using the provided cables. Follow the manufacturer's guidelines for network configuration.

3. Preparing the Printer

Before starting your first print job, perform the following preparation steps:

- Ink Installation: Install the UV-curable inks into their designated cartridges or reservoirs. Ensure the inks are properly seated and aligned according to the printer’s instructions.

- Media Loading: Load the film or transfer media onto the printer’s feed mechanism. Make sure the media is correctly aligned and free of wrinkles or creases.

- Calibration and Alignment: Run the printer’s calibration and alignment procedures to ensure accurate color reproduction and print head positioning. This may involve printing test patterns and adjusting settings as needed.

4. Design and File Preparation

Creating high-quality prints starts with well-prepared design files. Follow these tips for optimal results:

- File Format: Use compatible file formats such as TIFF, PNG, or PDF. Ensure your design files are in high resolution to achieve sharp, detailed prints.

- Color Management: Utilize color profiles that match the printer’s capabilities. This ensures accurate color reproduction and consistency across prints.

- Design Considerations: Consider the specific requirements of your substrate and the intended final product. Adjust your design elements accordingly to account for factors such as size, placement, and resolution.

5. Printing Process

With your setup complete and files prepared, you’re ready to start printing:

- Printer Settings: Configure the printer settings based on your media type and design requirements. Adjust parameters such as print resolution, ink density, and curing time as needed.

- Test Prints: Run test prints to verify settings and ensure print quality. This step helps identify any adjustments needed before proceeding with production runs.

- Production Runs: Once satisfied with the test prints, proceed with your production runs. Monitor the printer during operation to ensure smooth performance and address any issues promptly.

6. Post-Printing Process

After printing, follow these steps to ensure the best results and maintain your equipment:

- Curing and Drying: Allow the prints to fully cure under UV light as per the printer’s specifications. This step is crucial for ensuring the durability and longevity of the prints.

- Finishing: Depending on the application, you may need to apply additional finishes or coatings to enhance the appearance and functionality of the printed items.

- Maintenance: Regularly clean and maintain the printer according to the manufacturer’s guidelines. This includes cleaning print heads, checking ink levels, and performing routine inspections to ensure optimal performance.

7. Troubleshooting and Tips

Even with advanced technology, occasional issues may arise. Here are some common troubleshooting tips:

- Print Quality Issues: If you notice problems with print quality, such as streaks or color inconsistencies, check for clogged print heads, incorrect settings, or issues with the media.

- Ink Problems: Ensure that the ink cartridges are properly installed and not empty. Perform nozzle checks and cleaning cycles as needed to address any ink flow issues.

- Media Handling: If the media is not feeding correctly, check for obstructions or misalignment in the feed mechanism. Adjust the media guides and ensure proper tension.

8. Optimizing Your Workflow

To maximize the benefits of the MTuTech UV DTF Printer, consider implementing the following strategies:

- Efficient Workflow: Develop a streamlined workflow for file preparation, printing, and finishing to increase productivity and reduce turnaround times.

- Regular Training: Provide ongoing training for your team to ensure they are familiar with the printer’s features and best practices. This helps maintain high-quality standards and efficient operation.

- Stay Updated: Keep abreast of new developments and updates from MTuTech to take advantage of any new features or enhancements that can further improve your printing processes.

Conclusion: Mastering Your MTuTech UV DTF Printer

The MTuTech UV DTF Printer offers powerful capabilities for achieving high-quality, versatile prints. By following this guide, you can effectively set up, operate, and maintain your printer, ensuring optimal performance and creative freedom. Embrace the potential of this advanced technology to elevate your print shop’s offerings, enhance your design capabilities, and achieve outstanding results.